Convergence of Human-Centric and Tech-Driven Models for Industry 5.0

The Fourth Industrial Revolution, commonly known as Industry 4.0, transformed manufacturing and industry through the integration of “smart” technologies. Main components included artificial intelligence (AI), cloud connectivity, and real-time data analytics. This era primarily focused on enhancing efficiency, productivity, and developing cyber-physical systems.

Building on the foundation laid by Industry 4.0, which centered on digital transformation within manufacturing and supply chains, Industry 5.0 introduces a new model. It emphasizes a more deep and effective collaboration between humans and the intelligent systems within their digital environment. This partnership aims to combine the precision and speed inherent in industrial automation with the uniquely human attributes of creativity, innovation, and critical thinking.

Consumer demands for speed and customization are constantly increasing in today’s time and Industry 5.0 technologies offer a powerful solution. Businesses can achieve optimal outcomes by creating this synergy between human ingenuity and mechanized efficiency.

The evolution of industry has been marked by significant shifts, each driven by groundbreaking technological advancements. The first three Industrial Revolutions were ignited by transformative innovations- the steam engine’s power, the assembly line’s efficiency, and the computer’s rapid processing capabilities. These periods earned the “revolution” moniker because their underlying technologies fundamentally altered business practices and manufacturing processes.

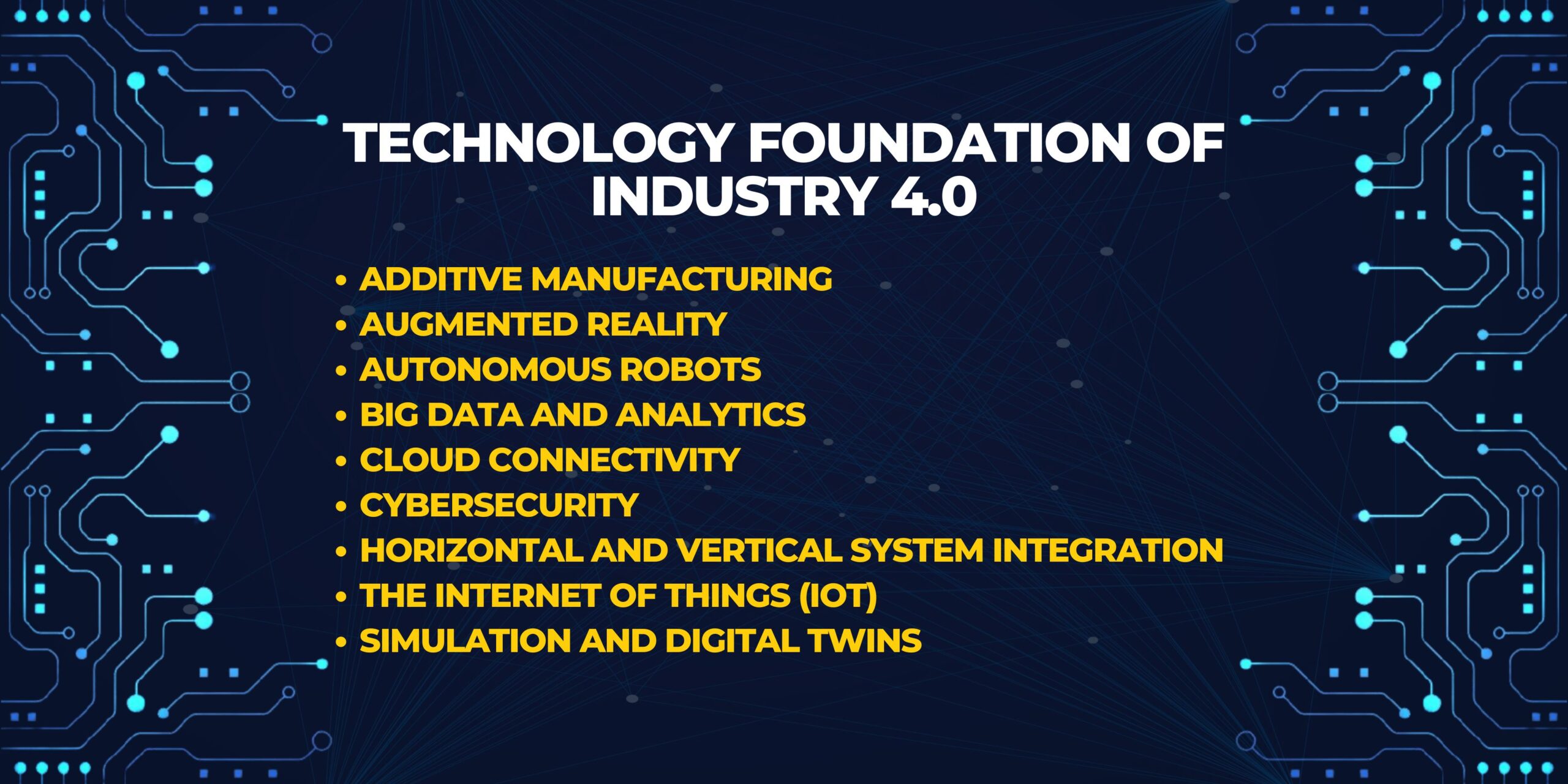

The Smart Technology Foundation of Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, is built upon the foundation of intelligent technologies. It is the prerequisite for any progress seen in Industry 5.0 and is characterized by nine essential components

Enhancing Human-Robot Collaboration in Industry 5.0

Industry 5.0 isn’t a separate industrial revolution but rather an enhancement of Industry 4.0 technologies. Its core focus is on strengthening the synergy between humans and robots. It expands upon the nine pillars of Industry 4.0 by prioritizing human creativity and well-being within industrial processes, aiming to integrate the speed and efficiency of machine technology with the ingenuity and skills of human workers.

- Human-Centric Approach– This principle places human needs and interests at the core of production. Instead of focusing on how workers can adapt to new technology, Industry 5.0 explores how technology can better serve workers. While robots offer tireless precision, they lack the critical and creative thinking abilities inherent in their human counterparts. Robots can fulfill their purpose of providing assistance and improving human lives by working alongside people.

- Sustainable Industry- This aspect drives businesses to minimize their environmental impact through the development of circular economy processes. Other sustainability goals include reducing energy consumption, greenhouse gas emissions, and waste, while also preventing the depletion and degradation of natural resources.

- Resilient Industry– Industrial production within a resilient framework exhibits a high degree of robustness, making it well-equipped to handle disruptions and support critical infrastructure during crises. The recent pandemic highlighted vulnerabilities in industrial systems, showing the importance of increased agility and resilience in supply chains and manufacturing operations.

Blending Industry 5.0 with Industry 4.0

Industry 5.0 introduces a pattern shift, superimposing value-driven, human-centric principles onto the technological bedrock of Industry 4.0. This fusion aims to create a more fluid and symbiotic relationship between human intelligence and machine capabilities.

- Adaptive Human-Machine Interfaces– The interaction between humans and machines can be tailored and refined by deploying embedded sensors, actuators, and machine learning algorithms, thus enabling collaborative robots (cobots) to adjust dynamically to human needs and actions.

- AI-Enhanced Collaborative Systems– The evolution of AI-driven human-robot collaboration is proving instrumental in optimizing resource utilization, mitigating waste, and supporting adherence to sustainability standards.

- Intelligent Data Management and Analytics– Sophisticated data management and analysis platforms, powered by artificial intelligence and machine learning, are important for identifying and eliminating inefficiencies, thereby optimizing human potential and operational workflows.

- Virtual Prototyping and Digital Twins– Utilizing simulation models and digital twin technology significantly reduces the strain on physical systems while simultaneously enhancing human learning and operational effectiveness. This approach promotes an environment where innovation and creative problem-solving can flourish with minimal associated operational hazards.

- Augmented Collaboration and Immersive Tools– The combination of collaborative robots and immersive experiences like virtual reality (VR) empowers organizations to amplify the benefits of smart automation while simultaneously harnessing the unique creativity and problem-solving ability inherent in human-robot partnerships.

Advantages of Industry 5.0 in Tomorrow’s Factories

Embracing the principles of Industry 5.0 offers significant long-term benefits that directly align with its foundational values. These include an enhanced ability to attract and keep skilled employees, substantial energy efficiencies, and bolstered overall operational resilience. Such advantages are important for businesses aiming to boost their competitive edge and maintain relevance in an evolving global landscape and emerging markets.

Attracting and Retaining Top Talent

Organizations increasingly struggle to secure and retain the specialized and talented workforce necessary for success today. When roles are limited to routine machine operation, employees often miss out on the intellectual stimulation and creative involvement that are vital for human achievement. Industry 5.0, with its advanced concepts and technologies, promotes a more dynamic and engaging workplace. This can significantly contribute to higher employee satisfaction and greater loyalty.

Driving Sustainability and Competitiveness

Sustainable practices are no longer merely desirable but are now a fundamental expectation from stakeholders across the business spectrum, particularly within resource and energy-intensive sectors. Companies that proactively integrate sustainability into their operations become more appealing to prospective investors, employees, and consumers. Implementing Industry 5.0 methodologies not only enhances the economic performance of industries but also simultaneously champions environmental stewardship.

Building Business Resilience

The capacity to respond effectively to disruptive events, be it trade disputes, global pandemics, or the effects of climate change, has become indispensable for business continuity. Industry 5.0 technologies are pivotal in cultivating industrial agility and resilience. They achieve this through comprehensive data collection, automated risk assessment, and reinforced security measures.

The integration of Industry 5.0 alongside Industry 4.0 offers significant advancements for the workforce. This synergistic approach emphasizes the close collaboration between highly skilled human workers and collaborative robots, or cobots, thereby augmenting the overall value in production. These advanced machines are outfitted with sensors, actuators, and AI-driven controllers, enabling them to operate safely and seamlessly alongside humans. Cobots are recognized for their adaptability, ease of programming, inherent safety features, and user-friendly design.

What are Cobots?

A cobot is essentially a robotic partner that assists or guides human workers, contrasting with autonomous robots that function independently after programming. Cobots are specifically engineered to react to human directives and actions. This partnership creates a synergistic relationship, combining the inherent strengths of both humans and machines to efficiently complete various tasks or processes.

Innovation Through Human-Cobot Collaboration

The partnership between humans and cobots has the potential to spark significant innovation. Consider the designer fashion industry- cobots could handle tasks like fabric collection, cutting, holding, or even sewing, while designers simultaneously sketch and drape materials on virtual 3D models using computers or VR. This seamless interaction could accelerate the creation and delivery of personalized designer clothing, potentially enabling same-day fulfillment.

The Dawn of Personalized Manufacturing

The convergence of collaborative robots (cobots) and human ingenuity is making the way for unprecedented levels of personalization and customization in industrial production. Cobots handle repetitive tasks with remarkable precision and consistency, freeing human workers to supervise operations and translate real-time customization requests into tangible products.

Several Industry 5.0 tools are accelerating this shift towards customizable manufacturing, like

- Integrated data platforms are important for gathering, storing, and analyzing customer input, transforming raw data into actionable insights for manufacturers.

- Digital twins and simulations enable rapid and cost-effective prototyping, helping manufacturers efficiently meet diverse customer specifications.

- Advanced AI and machine learning systems are becoming adept at understanding and predicting customer preferences, streamlining the production of bespoke components.

- Enhanced sensory tools (including high-precision sensors, actuators, 3D scanners, and virtual reality) are making the customization process more intuitive and accessible for both employees and consumers.

It envisions a factory environment where creativity thrives, creating a more human-centric experience for everyone involved in the manufacturing process.

Your Path to Industry 5.0 Transformation

Commencing the journey to Industry 5.0 requires thoughtful preparation. Key to this evolution are meticulous planning, robust strategies, transparent and inclusive communication, and a solid base of Industry 4.0 principles. It’s highly beneficial to start exploring potential solutions for your company’s specific objectives and hurdles sooner rather than later, as this will lay the groundwork for a successful transition to both Industry 4.0 and Industry 5.0.

References

https://www.linkedin.com/pulse/industry-50-human-machine-convergence-bill-palifka-nkmcc/

https://www.sap.com/romania/resources/industry-5-0

https://journalofcloudcomputing.springeropen.com/articles/10.1186/s13677-022-00314-5